Model No.: SL-1200

Brand: SUMAC

Place Of Origin: China

Types Of: Tire Machine

Old And New: New

Video Factory Inspection: Provided

Mechanical Test Report: Not Available

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Engine, Bearing, Motor

Tyre Machinery Type: Tire Recycling Machine

Warranty Period: 1 Year

Core Selling Point: Long Service Life

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Other

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

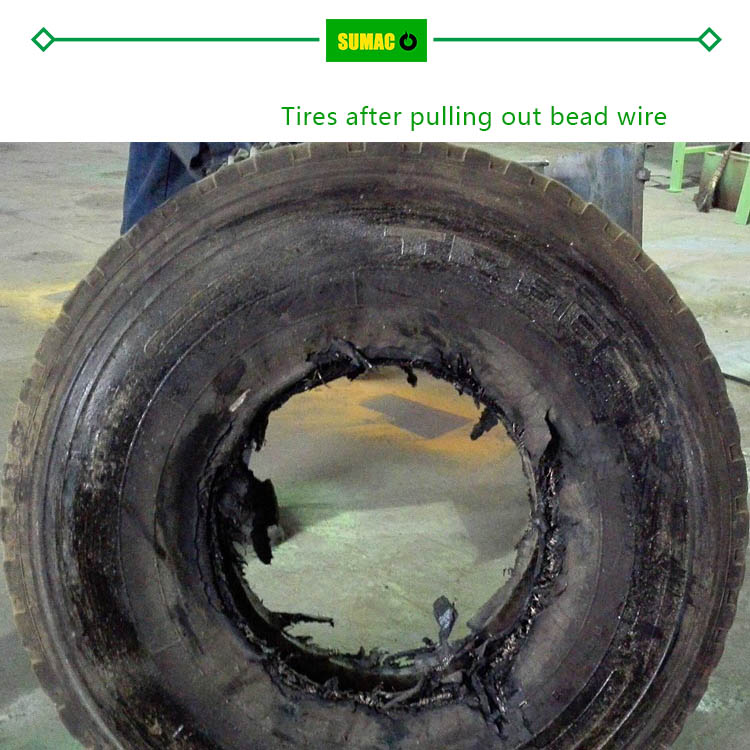

Name: Wasted tire recycling bead steel wire separator machine

Capacity: 60~100 pcs/hour

Outer Diameter Of The Tire: ≤ 1200 mm

Pulling Force: 30 T, 30T

System: Circuit protection system

Dimension: 2250x1660x1500mm

End Product: No tire bead wire

Machine Type: Double hooks

Weight: 6500kg