Tyre recycling waste tire rubber milling machine

Get Latest Price| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Tyre recycling waste tire rubber milling machine |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Tyre recycling waste tire rubber milling machine |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

Model No.: CXFJ-28

Brand: SUMAC

Place Of Origin: China

Types Of: Tire Machine

Old And New: New

Video Factory Inspection: Provided

Mechanical Test Report: Not Available

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor

Tyre Machinery Type: Tire Recycling Machine

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Other

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Name: Tyre recycling waste tire rubber milling machine

Raw Materials: All kinds of waste rubber

Max Size Of Raw Material: Out-diameter of waste tires less than 1300mm

Input Size: 1-4mm

Output Size: 30-100mesh

Capacity: 40-150Kg/h

Cooler: Water cooling

Operation: Automatic Electric Buttons Controller

Disc Diameter: 280mm

Feeding Mode: Servo motor

| Selling Units | : | Set/Sets |

| Package Type | : | 1. LCL, plastic film packed the whole machine, wooden case packed. 2. FCL, plastic film packed the whole machine, loaded into container. |

| Picture Example | : |

|

Introduction of Rubber Mill

Technical Specifications

| Model | CXFJ-28 Rubber Mill |

| Power | 30.2 kw |

| Size of input | 1-4 mm |

| Size of output | 30-100mesh |

| Capacity | 40-150 kg/h |

| Grinding Temp | =<30 °C |

| Weight | 1200 kg |

| Dimension | 1920x1250x1320 mm |

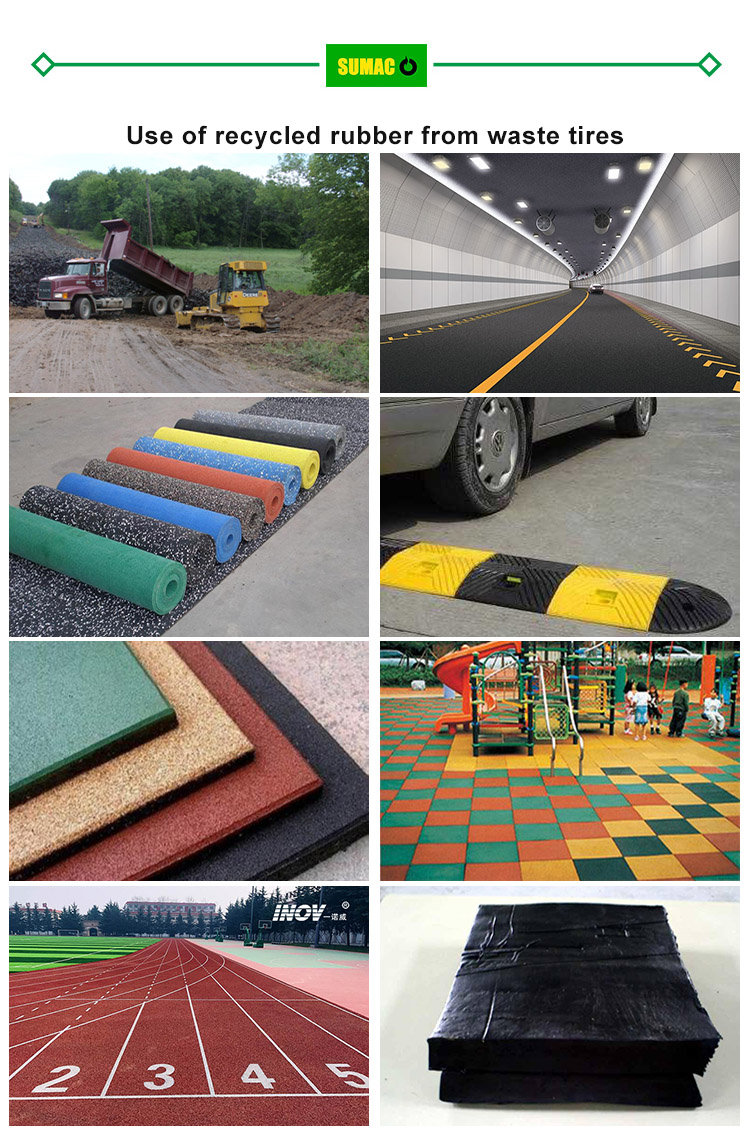

End Product

Packing & Delivery

Application

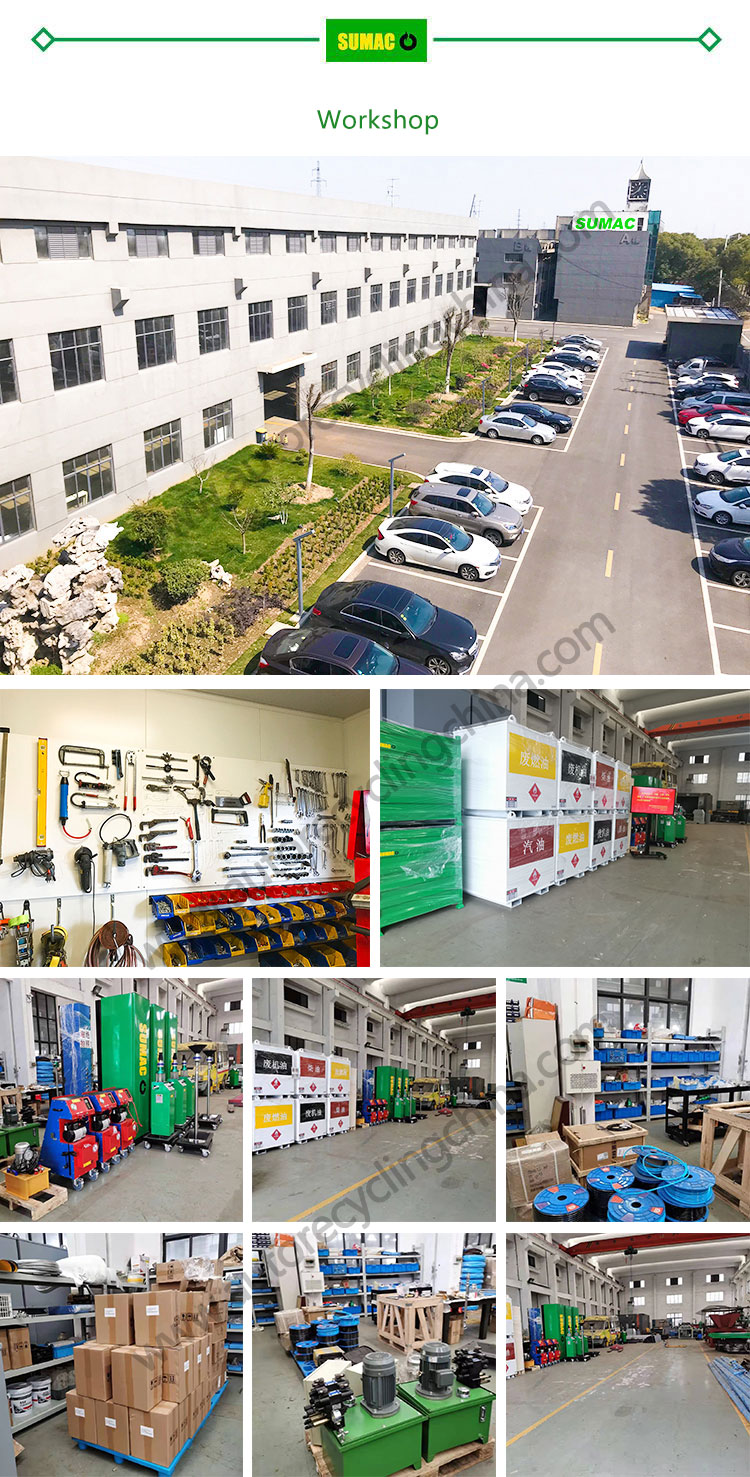

Company Information

Successful case

Services

We have our own brand, currently the sales region covers many countries and regions around the world.

All of our machinery are quite popular and welcomed by the clients all over the world.

It will be our great honor if you become one of our dealers.

We provide OEM/ODM services

We can do OEM lasers of your brand based on your special requirements.

Timely after-sale service

We have a professional technology supporting team for providing timely services.

If you have any problems, please contact us by telephone, email or WhatsApp.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.